Tired of slow production, inconsistent quality, or high defect rates in your adult toy manufacturing? These issues can eat into profits and damage your brand. Let’s explore how optimizing injection molding can be a game-changer.

Optimizing the injection molding process for adult toys involves fine-tuning material selection and preparation, mold design, machine parameters (like temperature, pressure, and speed), cooling times, and post-processing. This holistic approach enhances efficiency, quality, and reduces waste, ultimately boosting your bottom line and customer satisfaction. It’s about smart, incremental improvements at each stage.

Alright, so you get the gist: tweaking the injection molding process is key. But as someone who’s been in the trenches of adult product manufacturing for years, founding PrivyPlay and seeing all sorts of production challenges, I can tell you it’s more than just a technical checklist. It’s about understanding the nuances, the interplay between materials, machines, and even the design of the toy itself. Getting this right means smoother production runs, happier customers, and honestly, fewer headaches for us brand owners and sourcing managers. I’ve seen firsthand how a well-optimized process can transform a product line from problematic to profitable. So, let’s dig into how we can really nail this.

What Are the Core Stages of Injection Molding for Our Toys, and Where Are the Optimization Sweet Spots?

Feeling overwhelmed by the complexity of injection molding and unsure where to even start looking for improvements? A clunky process means delays and defects, hitting your timelines and quality. Let’s break down the stages and pinpoint where we can make things better.

The core stages are: material preparation, mold clamping, injection, cooling, and ejection. Optimization sweet spots include precise material drying, intelligent mold design for flow and cooling, dialed-in injection pressures and speeds, optimized cooling cycles, and efficient ejection mechanisms to prevent damage and reduce cycle times.

When I first got deep into manufacturing our PrivyPlay line, understanding each step of injection molding felt like learning a new language. But once you break it down, you start seeing all these little opportunities to make things run smoother, faster, and with better results. It’s not about one magic fix; it’s about a series of smart adjustments.

Deeper Dive: Unpacking the Stages and Finding Efficiencies

Let’s walk through the typical injection molding journey and highlight where we can sprinkle some optimization magic. This isn’t just theory; these are areas where I’ve seen real impact.

-

1. Material Preparation: The Foundation

- What it is: Getting your chosen plastic (like ABS) or elastomer (like TPE or liquid silicone rubber – LSR) ready. This often involves drying the material to remove moisture, which can cause defects.

- Optimization: Don’t skimp here! Using precise drying equipment and ensuring materials are at the optimal moisture content before they hit the machine is crucial. For instance, with some TPEs, if they’re too moist, you get splay marks or bubbles. We once had a batch issue, and it all traced back to an improperly calibrated dryer. Investing in good drying systems and protocols pays off big time.

-

2. Mold Clamping & Injection: The Main Event

- What it is: The two halves of the mold are clamped shut under high pressure. The molten material is then injected into the mold cavity.

- Optimization:

- Mold Design: This is HUGE. Optimizing gate locations (where material enters) and runner systems (channels that guide material) ensures even filling and reduces issues like short shots or weld lines. We work closely with our mold makers on simulations before steel is cut.

- Machine Parameters: Fine-tuning injection pressure, speed, and temperature for the specific material and toy design is an art and a science. Too slow, and it might cool prematurely; too fast, and you can get flash.

-

3. Cooling: Patience is a Virtue (but not too much!)

- What it is: The molten material cools and solidifies within the mold, taking the shape of the cavity.

- Optimization: This is often the longest part of the cycle. Efficient cooling channel design within the mold is paramount. Using chilled water and ensuring consistent mold temperature can significantly shorten cooling time without causing warping. We’ve experimented with conformal cooling channels in some of our newer molds, and the cycle time reduction was noticeable.

-

4. Ejection & Post-Processing: The Finish Line

- What it is: The mold opens, and the solidified part is ejected. Some parts might need trimming (de-gating) or other minor finishing.

- Optimization: Well-placed ejector pins and a good mold release agent (if needed and material-compatible) ensure smooth ejection without damaging the toy. Automating de-gating or using hot runner systems (more on that later) can minimize post-processing labor.

Think of it like a relay race; each stage needs to hand off perfectly to the next. A bottleneck or error in one stage impacts the entire process.

| Stage | Common Issue | Optimization Strategy |

|---|---|---|

| Material Prep | Splay, Bubbles | Proper drying, consistent material blending |

| Injection | Short Shots, Flash | Optimized gate/runner, precise parameters |

| Cooling | Warping, Long Cycles | Efficient cooling channels, temp control |

| Ejection | Part Damage, Sticking | Strategic ejector pins, mold release |

Focusing on these areas has helped us at PrivyPlay streamline things considerably. It’s an ongoing process of refinement, but the results speak for themselves.

How Does Our Choice of Material—Silicone, TPE, or ABS—Shake Up the Injection Molding Game?

Ever wonder why one toy design is a breeze to mold while another, seemingly similar, causes endless headaches? Often, the material itself is the culprit, behaving differently under the pressures and temperatures of injection molding. This can throw your production efficiency way off.

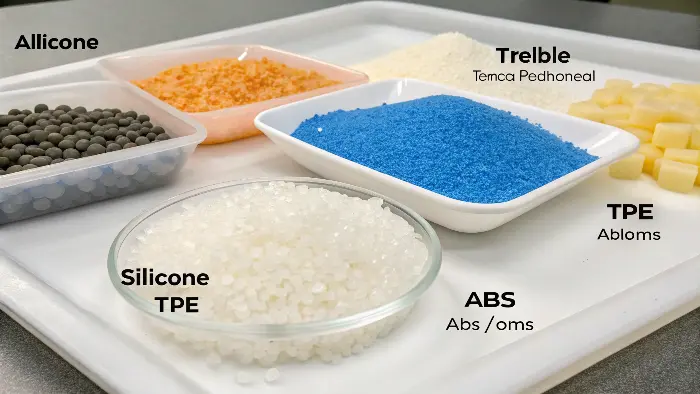

Material choice profoundly impacts injection molding. Silicone (especially LSR) requires specialized cold runner systems and different curing processes. TPEs vary widely in flowability and stickiness, affecting cycle times and mold release. ABS, being rigid, generally flows well but needs precise temperature control to avoid degradation or warping.

I learned this the hard way early on. You can’t just swap out TPE for silicone in the same mold with the same settings and expect magic. Each material has its own personality, its own demands on the injection molding process. Understanding these differences is key to efficient production for brands like ours.

Deeper Dive: Material-Specific Molding Considerations

Let’s look at how our common adult toy materials – Liquid Silicone Rubber (LSR), Thermoplastic Elastomers (TPE), and Acrylonitrile Butadiene Styrene (ABS) – behave in the injection molding machine and what that means for optimization.

-

Liquid Silicone Rubber (LSR) Molding:

- Process: LSR molding is quite different. It typically involves a two-part liquid compound that’s mixed before being injected into a heated mold where it cures (vulcanizes). This often uses a "cold runner" system to keep the material cool until it enters the hot cavity.

- Optimization: Precision in mixing ratios is critical. Mold temperature control is paramount for consistent curing. Cycle times can be optimized by efficient heating and cooling of the mold, and specialized mold coatings can aid release, as silicone can be quite sticky. For PrivyPlay’s premium silicone line, we invested in dedicated LSR machines and molds because the process is so distinct. The quality and feel are worth it, but it’s a different ball game.

-

Thermoplastic Elastomer (TPE) Molding:

- Process: TPEs are processed more like traditional thermoplastics – melted and injected into a cooled mold. However, their "softness" and "stickiness" vary wildly between grades.

- Optimization: Flowability is a big factor. Softer TPEs might need wider gates and runners. Stickiness can make ejection tricky, so mold surface finish, draft angles, and ejector pin design are crucial. Cooling times can also be longer for thicker TPE parts. We often run multiple trials with different TPE grades to find the one that gives the best feel and molds efficiently for a particular design. Some TPEs are also prone to stringing, so nozzle temperature and suck-back settings need careful adjustment.

-

Acrylonitrile Butadiene Styrene (ABS) Molding:

- Process: ABS is a rigid thermoplastic. It generally flows well when molten and fills intricate details.

- Optimization: Proper drying is essential to prevent cosmetic defects. Melt temperature needs to be carefully controlled – too low, and you get short shots; too high, and the material can degrade, affecting its strength and appearance. Uniform mold cooling is important to prevent warping, especially in larger or flatter ABS parts. For internal components or hard casings in PrivyPlay products, ABS is great, but we always ensure our mold cooling is top-notch.

Here’s a quick comparison:

| Material Feature | LSR (Silicone) | TPE | ABS |

|---|---|---|---|

| Mold Temp | Heated (for curing) | Cooled | Cooled |

| Runner System | Often Cold Runner | Hot or Cold Runner | Hot or Cold Runner |

| Key Challenge | Mixing, Curing, Stickiness | Flow, Stickiness, Cycle Time | Warping, Degradation if overheated |

| Processing Temp | Lower injection, high mold | Varies widely by grade | Moderate to High Melt Temp |

| Typical Use | High-end flexible toys | Soft, skin-like toys, overmolding | Rigid casings, internal parts, handles |

Understanding these material-specific nuances allows us to select the right grade for the application and then tailor the molding process for optimal results. It’s a constant learning curve, especially as new material formulations come out!

Are There Any Cool New Tricks or Tech to Make Our Injection Molding Faster and Smarter?

Are you stuck using the same old injection molding methods while your competitors seem to be churning out products faster and with better consistency? Falling behind on tech can mean losing your edge. So, what advanced techniques can give us a boost?

Yes! Advanced techniques like multi-cavity molds, hot runner systems, automation (robotics for part removal and packing), and process simulation software can significantly enhance injection molding. Real-time monitoring and AI-driven process adjustments are also emerging as powerful tools for optimization.

I’m always on the lookout for ways to make our PrivyPlay production more efficient without compromising quality. It’s not just about getting more toys out the door; it’s about doing it smarter, with less waste, and with even better precision. Some of these "new tricks" aren’t even that new, but their adoption and refinement are making a big difference.

Deeper Dive: Supercharging Your Molding Operations

Let’s explore some of these technologies and how they can elevate your injection molding game. Some of these we’ve implemented, and others are high on our R&D list.

-

Multi-Cavity Molds:

- What it is: Instead of making one part per cycle, the mold has multiple identical cavities, producing several parts simultaneously.

- Impact: Drastically increases output per machine hour. The upfront cost of the mold is higher, but for high-volume products, the per-part cost plummets. We use multi-cavity molds for some of our best-selling smaller items, and the throughput is fantastic. The key is ensuring all cavities fill and cool uniformly – that takes expert mold design.

-

Hot Runner Systems:

- What it is: These systems keep the plastic in the runners (the channels leading to the cavities) molten. In traditional "cold runner" systems, the runner solidifies with the part and has to be removed (and often reground or discarded).

- Impact: Reduces material waste significantly, shortens cycle times (no runner to cool), and often improves part consistency because the melt delivery is more direct. The molds are more complex and expensive, but the material savings and cycle time benefits can be huge, especially with pricier engineering resins or even some TPEs. We’re gradually shifting more of our TPE production to hot runner molds.

-

Automation & Robotics:

- What it is: Using robots for tasks like removing parts from the mold, de-gating, inspection, or packing.

- Impact: Increases consistency, reduces labor costs, and can speed up cycle times as robots can operate with high precision and without breaks. For delicate parts or those requiring precise handling, robotics can also reduce damage. We’ve started using simple robotic arms for part removal on a couple of our lines, and it’s made a noticeable difference in consistency and freeing up our human operators for more skilled tasks.

-

Process Simulation Software:

- What it is: Software (like Moldflow) that simulates how the molten plastic will flow into the mold, cool, and potentially warp before the mold is even built.

- Impact: Allows designers and engineers to identify potential problems (like air traps, weld lines, or uneven filling) and optimize mold design (gate locations, cooling channels) virtually. This saves a ton of time and money by avoiding costly mold rework. I insist our team uses this for any new complex toy design. It’s like having a crystal ball for molding!

-

Real-Time Monitoring & AI:

- What it is: Sensors on the molding machine collect data on pressure, temperature, cycle time, etc. This data can be analyzed in real-time, and increasingly, AI algorithms can suggest or even automatically make micro-adjustments to the process to maintain optimal conditions and predict potential issues.

- Impact: Leads to more stable processes, higher quality, and reduced downtime. This is cutting-edge stuff, and while we’re not fully there yet at PrivyPlay, we’re actively exploring systems that offer better real-time data analytics. The potential for "self-optimizing" machines is incredibly exciting!

These technologies aren’t just fancy add-ons; they represent a shift towards more intelligent, efficient, and sustainable manufacturing. Investing wisely here can give you a serious competitive advantage.

How Do We Kick Common Injection Molding Defects to the Curb and Slash Waste?

Are you constantly battling issues like flash, sink marks, or short shots in your molded adult toys? These defects mean rejected parts, wasted material, and frustrated customers. It’s a drain on resources and reputation. So, how do we get a handle on these problems?

Minimizing defects involves a multi-pronged approach: meticulous mold design and maintenance, precise control of material quality and processing parameters (temperature, pressure, speed), and ensuring proper venting and cooling within the mold. Regular process audits and operator training are also key to catching and correcting issues early.

Oh, the battles I’ve fought with molding defects! Early in my PrivyPlay journey, we had this one particularly tricky TPE design that was prone to "flash" – that annoying thin layer of excess material seeping out of the mold. It drove us nuts! Solving these issues isn’t just about saving a few pennies on wasted material; it’s about upholding the quality your customers expect.

Deeper Dive: Tackling Top Molding Gremlins

Let’s look at some of the usual suspects when it comes to injection molding defects and how to show them the door. This is where the rubber (or silicone, or TPE!) meets the road in terms of quality control.

-

1. Flash (Excess Material):

- Cause: Mold halves not clamping tightly enough, injection pressure too high, worn-out mold parting lines, or material too fluid.

- Solution: Check clamp tonnage, reduce injection pressure/speed, inspect and repair mold parting lines. Ensure the material viscosity is appropriate for the part and mold design. Sometimes, simply adjusting the mold temperature can help. That flash issue I mentioned? It turned out to be a combination of slightly too high injection pressure and a tiny bit of wear on the mold. A little tweaking and a minor mold touch-up, and problem solved!

-

2. Short Shots (Incomplete Parts):

- Cause: Insufficient material injected, material too viscous or cooling too quickly, blocked gates/runners, or inadequate venting preventing air from escaping.

- Solution: Increase shot size or injection pressure, raise melt/mold temperature, check for blockages, and ensure mold vents are clear and adequate. Proper mold design with good venting is critical here.

-

3. Sink Marks (Surface Depressions):

- Cause: Uneven cooling or insufficient packing pressure, often in thicker sections of the part where the material shrinks more as it cools.

- Solution: Optimize part design to avoid overly thick sections (core them out if possible), increase holding pressure and time, ensure adequate cooling in thicker areas, or lower melt/mold temperature. This one often requires a good look at the part design itself.

-

4. Warping (Distortion):

- Cause: Uneven cooling rates across the part, high residual stresses from molding, or improper ejection.

- Solution: Optimize cooling channel design for uniform mold temperature, adjust packing pressure, ensure parts are fully cooled before ejection, and check that ejector pins are balanced and not distorting the part. Sometimes, a longer cycle time is unavoidable to prevent warping in complex shapes.

-

5. Burn Marks (Discoloration):

- Cause: Trapped air overheating due to compression, or material degradation from excessive temperature or shear.

- Solution: Improve mold venting, reduce injection speed or melt temperature, and ensure the nozzle and barrel temperatures aren’t too high.

Proactive Strategies for Defect Prevention:

| Strategy | Action | Impact on Defects |

|---|---|---|

| Mold Maintenance | Regular cleaning, inspection, and repair of molds. | Reduces flash, sticking, surface imperfections. |

| Process Control | Consistent monitoring and adjustment of machine parameters. | Minimizes variations that lead to most defects. |

| Material Quality | Using high-quality, properly dried materials from trusted suppliers. | Prevents issues like splay, brittleness. |

| Operator Training | Educating operators on defect identification and basic troubleshooting. | Enables quick response to emerging problems. |

At PrivyPlay, we have a "defect library" with examples of common issues and their root causes. It’s a great training tool and helps us standardize our troubleshooting. Reducing defects isn’t a one-time fix; it’s about building a culture of quality and continuous improvement. It’s definitely worth the effort!

Conclusion

Optimizing injection molding is a journey, not a destination. By focusing on materials, process stages, embracing new tech, and diligently tackling defects, we can make better adult toys, more efficiently. It’s about smart work, not just hard work! 👍