We’ve all heard the horror stories. A customer’s brand-new toy is accidentally dropped, and it shatters into pieces. This isn’t just an inconvenience; it’s a direct blow to your brand’s reputation. You need a way to ensure your products are built to last.

To guarantee your adult products withstand impact, you must use industry-standard testing methods like ASTM D256 (Izod test) for plastics and develop custom drop-test protocols. These tests simulate real-world accidents, like dropping a toy on a hard floor. This ensures the materials and construction of your products are durable, preventing breakage, protecting your brand’s reputation, and ensuring customer safety.

As someone who has spent years in the manufacturing side of this industry, I’ve seen firsthand what separates a premium product from a cheap one. It often comes down to the unseen details, and impact resistance is one of the most important. It’s not just about passing a test on a spec sheet; it’s about a commitment to quality that your customers can literally feel. Let’s explore what that means in practice and how you can build that same level of trust into your own product line.

Why is Impact Resistance Testing So Critical for Adult Products?

You’ve invested heavily in design and marketing, assuming your product is durable. But what if it’s not? A single batch made with a slightly more brittle material could trigger a wave of customer complaints, returns, and negative reviews, undoing all your hard work. Proactive impact testing is not an expense; it’s a crucial investment in your brand’s future.

Impact resistance testing is critical because it directly relates to customer safety, product longevity, and brand reputation. A product that breaks can create sharp edges, posing an injury risk. Furthermore, durable products lead to higher customer satisfaction and fewer reviews. In an intimate market, trust is everything, and robust testing is how you build and maintain that trust.

In my experience, durability is about more than just a product not breaking. It sends a powerful message to your customer about the quality and value of your brand. When a customer holds your product, it should feel solid and reliable. That feeling of quality is often subconscious, but it’s built on very conscious engineering and testing choices.

Beyond the Obvious: Safety First

Let’s be direct. When an adult toy breaks, it’s not like dropping a coffee mug. If a plastic casing shatters, it can create dangerously sharp fragments. If the internal housing cracks, it could expose wires, batteries, or motor components. This is a massive safety liability and a complete breach of the trust a customer places in you. Proper impact testing identifies weak points in the design or material before your product ever reaches a customer’s bedroom. It’s our fundamental responsibility as brand owners to ensure the products we sell are completely safe, even if they’re handled imperfectly.

The Financial Cost of Poor Durability

A product that fails in the field costs you money in multiple ways. First, there are the direct costs of processing returns and shipping replacements. These add up quickly and eat directly into your profit margins. Second is the damage to your brand reputation. In the age of social media and online reviews, one customer’s video of a broken product can reach thousands of potential buyers. The cost of acquiring a new customer is high, and losing them over a preventable quality issue is a painful, unforced error. Investing a small amount upfront in proper testing can save you a fortune in the long run.

What Are the Key ASTM Standards for Impact Resistance?

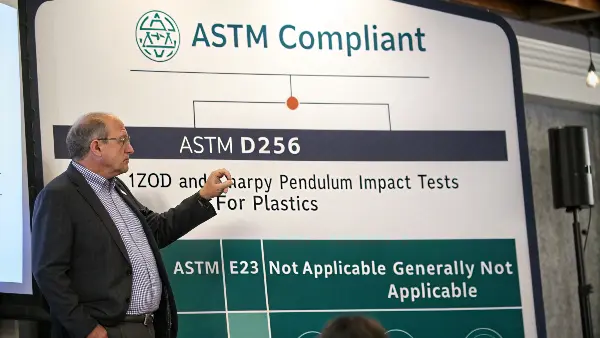

You see phrases like "ASTM compliant" on material data sheets, but what does that actually mean for your products? Without a clear understanding, you risk paying for irrelevant tests or, even worse, skipping the ones that truly matter. This can leave your products, and your brand, completely exposed to failure. Let’s clarify the key ASTM standards you need to know.

The most relevant ASTM standard for adult products is ASTM D256, which outlines the Izod and Charpy pendulum impact tests for plastics. ASTM E23 is for notched bar impact testing of metallic materials, which is generally not applicable. Therefore, focusing on ASTM D256 helps you quantify the impact resistance of materials like ABS plastic, ensuring they won’t crack or shatter under stress.

When I work with brand owners, one of the first things we discuss is materials. The choice of plastic is a critical decision. ASTM, which stands for the American Society for Testing and Materials, creates the standards that allow us to compare these materials with objective data. This isn’t about guesswork; it’s about making informed decisions based on scientific principles to build a better, stronger product.

ASTM D256: The Go-To for Plastics

This is the standard you should focus on. It describes a test to determine a plastic’s impact resistance. The most common method used here is the "Notched Izod Impact Test." In simple terms, a small, standardized sample of the plastic is created with a tiny notch in it to create a stress point. This sample is held firmly in a vise. Then, a weighted pendulum hammer is released, swinging down and striking the sample. The machine measures how much energy the sample absorbed before it fractured.

A higher energy absorption value means the material is tougher and less brittle. When you’re looking at data sheets for ABS plastic, polycarbonate, or other rigid materials for your toy’s housing, the Izod impact strength is a key number. It tells you exactly how well that material will resist a sudden shock—like being dropped.

Why ASTM E23 Usually Doesn’t Apply

You might also come across ASTM E23. It’s important to know what this is so you don’t waste time or money on it. ASTM E23 is also a pendulum impact test, but it is specifically designed for metallic materials. Unless your adult product has major structural components made of steel or aluminum, this test is irrelevant. For the vast majority of products in our industry, which rely on plastics, silicones, and elastomers, you can safely ignore ASTM E23 and keep your focus on D256.

How Do ISO Impact Testing Standards Compare to ASTM?

You might be designing your product in the USA, manufacturing it with a partner like me in China, and selling it to customers in Europe. This global supply chain can create confusion over standards. Using the wrong one can mean your product isn’t compliant in your target market, or that your test results are misinterpreted. Understanding the difference between ASTM and ISO is vital for any global brand.

ISO impact testing standards, like ISO 179 (Charpy test) and ISO 180 (Izod test), are the international equivalents to ASTM tests. While the fundamental principles are very similar—measuring a material’s ability to absorb energy—the sample dimensions and testing parameters can differ slightly. For global brands, ensuring your manufacturer can test to either standard provides maximum flexibility.

The International Organization for Standardization (ISO) works to create standards that are accepted globally. This is incredibly helpful for businesses like ours. When a material supplier gives me an ISO test result, I know exactly what it means, just as a client in Germany or Australia would. While ASTM is dominant in North America, ISO is the lingua franca for the rest of the world. Here’s how they stack up.

ISO 179/180 vs. ASTM D256: Key Differences

The core purpose is identical: to see how a material behaves under sudden impact. However, thedevil is in the details. The test methods specified by ISO and ASTM are not directly interchangeable because of small but significant differences in the test setup. A good manufacturing partner will understand this nuance.

Here is a simple breakdown:

| Feature | ASTM D256 (Izod) | ISO 180 (Izod) / ISO 179 (Charpy) | Note for Brand Owners |

|---|---|---|---|

| Primary Goal | Measure impact energy absorbed. | Measure impact energy absorbed. | The goal is identical: assess toughness. |

| Specimen Size | Standardized, often in inches. | Standardized, in metric units (mm). | The specimen size can differ. Your factory must use the correct mold for the specified test. |

| Notch Shape | V-notch is most common. | Options for different V- and U-notches. | The shape of the notch affects the result, so you must be consistent. |

| Global Reach | Dominant in North America. | Accepted globally, especially in Europe & Asia. | Specify the standard most relevant to your primary market. |

The most important takeaway here is that a result from an ISO test cannot be directly compared to an ASTM test result. They are two different languages telling a similar story. You must decide which standard is your benchmark, specify it clearly in your product requirements document, and stick with it for all your material comparisons.

How Do You Apply These Standards in Real-World Scenarios?

Lab data from an ASTM or ISO test is essential, but let’s be realistic: your customers are not using pendulum testers in their bedrooms. A product can be made from a tough material and still fail in the real world due to a weak point in the design or a flaw in assembly. To build a truly robust product, you must bridge the gap between lab data and real-life use with practical testing.

Apply these standards by first using tests like ASTM D256 to select durable raw materials (e.g., tough ABS plastic). Then, create a custom drop-test protocol for the finished, assembled product. For example, a "1-meter drop onto concrete" test simulates a common accident. This combination of material-level (ASTM/ISO) and product-level (drop test) testing provides complete quality assurance.

This two-step process is something I implement with all my clients at PrivyPlay. It moves quality assurance from a theoretical exercise to a practical guarantee. It’s how we ensure the final product that lands in your customer’s hands is as strong as the materials it’s made from.

Step 1: Material Selection Based on Data

Your journey starts with the Technical Data Sheet (TDS) for the raw materials you’re considering. Look for the "Notched Izod Impact Strength" value, usually measured in kilojoules per square meter (kJ/m²) or foot-pounds per inch (ft-lb/in). If you’re comparing two different grades of ABS plastic, the one with the higher Izod value will be more durable. Use this objective data to shortlist the best possible materials for your product’s casing or other rigid parts. Don’t just go with what’s cheapest; choose what’s right for the application.

Step 2: Designing and Implementing a Drop Test

Once you have prototypes or first production samples, it’s time for the drop test. This is a non-standardized test that you define based on likely real-world scenarios. Here’s how to create one:

- Define the Conditions: Be specific. For example: "Drop the product from a height of 1 meter onto a solid concrete surface."

- Define Failure: What counts as a fail? A "fail" could be a visible crack, a new rattle sound from loose internal parts, or the product no longer functioning electronically. You must define this clearly for your manufacturer.

- Test at Different Angles: A product’s weak points are often at its seams or tips. You should drop it multiple times, ensuring it lands on its base, its side, and its tip. This helps identify the most vulnerable spots.

- Document Everything: Require your manufacturing partner to document the tests with photos and videos. This creates accountability and provides clear evidence of whether the product passed or failed.

This simple, practical test tells you more about the final product’s real-world durability than any material test alone.

Conclusion

Ensuring your products are durable isn’t an option; it’s essential for customer safety, satisfaction, and your brand’s reputation. By combining material-level standards like ASTM and ISO with practical, real-world drop tests on the final product, you create a comprehensive quality system that protects everyone.