Your customers demand eco-friendly and body-safe products, but navigating the world of TPE formulations is complex. Choosing the wrong supplier means risking your brand’s reputation with unsafe materials or greenwashing claims. Understanding the future trends in TPE helps you make informed decisions and build trust.

The future of TPE is centered on sustainability, enhanced safety, and greater personalization. This involves using recyclable and bio-based materials, adhering to strict safety standards like EU regulations, and offering custom firmness and color options. These trends are driven by consumer demand for products that are both pleasurable and responsible, creating huge opportunities for forward-thinking brands.

We all see the buzzwords everywhere: "sustainable," "body-safe," "eco-friendly." But as brand owners and sourcing managers, we know that these terms can be hollow. The real value, and the key to building a brand that lasts, is in understanding what these trends truly mean on a manufacturing level. It’s about tangible changes in the raw materials, the production processes, and the types of verification you should demand from your partners. Let’s break down exactly what to look for and what questions you need to be asking.

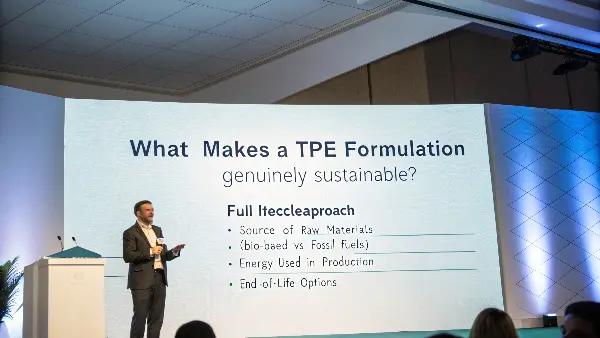

What Makes a TPE Formulation Genuinely Sustainable?

You want to market your products as "eco-friendly," but this term is thrown around so loosely it’s almost meaningless. Using a material that isn’t truly sustainable can lead to accusations of greenwashing from savvy customers, damaging the trust you’ve worked so hard to build.

Truly sustainable TPE goes beyond just being recyclable. It involves a full lifecycle approach, including the source of its raw materials (bio-based vs. fossil fuels), the energy used in production, and its end-of-life options. Look for formulations that are recyclable and, increasingly, those incorporating renewable, plant-based components to reduce your product’s carbon footprint.

For years, the main "green" talking point for TPE was that it’s recyclable. While true, that’s only a small part of the story. As conscious consumers push for more, our industry has to dig deeper. Sustainability isn’t a single feature; it’s a complete approach to how a product is made, used, and disposed of. For brand owners like us, this means we have to get smarter about the materials we choose and the partners we work with. It’s no longer enough to just tick a box that says "recyclable." We need to question the entire process.

Beyond Recyclability: The TPE Lifecycle

Most TPEs are technically recyclable, but this claim can be misleading. First, the recycling process itself requires energy and resources. Second, TPE is often "downcycled," meaning it’s turned into a lower-quality product, not back into a new adult toy. A truly sustainable approach considers the entire lifecycle. This starts with reducing reliance on virgin, petroleum-based plastics from the very beginning. As a manufacturer, I’ve seen a clear shift. The conversation is no longer just "Can we recycle this?" but "How can we make this with less environmental impact from day one?"

The Rise of Bio-Based TPE

This is where the real innovation is happening. Bio-based TPEs use raw materials derived from renewable resources like corn, sugarcane, or other plant-based sources. This is a game-changer because it directly reduces our dependence on fossil fuels. Early on, some bio-based formulations had issues with texture or durability, but material science has come a long way. Now, we can create bio-based TPEs that feel just as soft, flexible, and durable as traditional versions. When you can offer a product that feels amazing and has a lower carbon footprint, you have a powerful story to tell your customers.

Putting it into Practice: Questions for Your Supplier

Vetting a manufacturer on their sustainability claims is crucial. Don’t accept vague answers. Here are the questions you should be asking to separate the true partners from the greenwashers.

| Question to Ask Your Manufacturer | Why This Question Matters | Red Flag Answer | Green Flag Answer |

|---|---|---|---|

| Can you specify the source of your TPE? | This verifies if the material is petroleum-based or if it includes a percentage of bio-based content. | "It’s a high-quality, standard TPE." | "This formulation is a TPE-V with 30% bio-based content from certified renewable sources. We can provide the data sheet." |

| How is this material recycled? | This clarifies the real end-of-life options for your customer, moving beyond a simple "recyclable" claim. | "Yes, it is recyclable." (Vague) | "It’s a Type 7 plastic. We advise customers to check with local facilities, as not all accept it. We can provide disposal guidance." |

| What steps do you take to reduce energy in production? | This shows a commitment to sustainability that goes deeper than just the material itself. It speaks to their operational DNA. | "We focus on producing what you order." | "We’ve upgraded our molding machines to be 20% more energy-efficient and we recycle all our internal production scrap." |

How Can We Verify TPE Formulations are Truly Body-Safe?

The term "body-safe" is used for almost everything, but what does it actually guarantee? The frightening reality is that it often guarantees nothing. Using a TPE that contains harmful phthalates, heavy metals, or other toxins could lead to serious customer health issues, legal liability, and the complete destruction of your brand.

To verify TPE is truly body-safe, you must demand documentation from your manufacturer. This includes test reports from independent third-party labs confirming it is free of phthalates, latex, BPA, and heavy metals. Look for compliance with strict international standards like EU REACH or RoHS, which are more rigorous than many local regulations. Never rely on a supplier’s word alone.

I’ve been in this industry long enough to see brands rise and fall on the issue of safety. A few years ago, I worked with a new brand owner who focused only on getting a "phthalate-free" confirmation from their supplier. They assumed that was enough. Six months after launch, a random customs check in Germany flagged their shipment for containing unacceptable levels of cadmium, a heavy metal. Their entire inventory was seized, and their brand was tarnished overnight. This taught me a hard lesson: "body-safe" is not a marketing term. It is a technical standard that must be proven with evidence.

Moving Beyond Just "Phthalate-Free"

Being phthalate-free is the absolute bare minimum, the price of entry. It’s not a badge of honor anymore; it’s an expectation. Truly safe TPE must also be proven to be free from a host of other harmful substances. This includes things like Bisphenol A (BPA), which is an endocrine disruptor, and heavy metals like lead, mercury, and cadmium, which are toxic. A reputable manufacturer should be able to provide a comprehensive test report that checks for a wide range of potential contaminants, not just the most obvious one.

Key Global Safety Standards to Know

Not all safety standards are created equal. While many countries have their own regulations, some are far more comprehensive than others. As a brand owner, targeting compliance with the strictest standards ensures your product is safe for nearly any market in the world.

| Standard | What It Regulates | Why It’s Crucial for Adult Toys |

|---|---|---|

| EU REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals. | This is the gold standard. It regulates thousands of chemicals and requires companies to report on their safe use. If your supplier is REACH compliant, they are serious about safety. |

| RoHS | Restriction of Hazardous Substances. | Originally for electronics, this standard restricts the use of specific hazardous materials, including several heavy metals. Its principles are directly applicable to ensuring a toy is non-toxic. |

| Prop 65 (California) | Safe Drinking Water and Toxic Enforcement Act. | This requires businesses to warn about exposure to chemicals known to cause cancer or reproductive harm. A manufacturer who understands Prop 65 is attuned to the top tier of consumer safety concerns. |

The Non-Negotiable: Third-Party Testing

A manufacturer’s internal quality control is important, but it’s not enough. You must insist on seeing test reports from a reputable, independent, third-party laboratory (like SGS, Intertek, or TÜV). When you get a report, don’t just glance at it. Check the date (is it recent?), the batch or material number (does it match what you’re buying?), and the specific substances tested. A trustworthy partner will provide these reports without hesitation. If a supplier gets defensive or says, "just trust us," it’s a massive red flag. Walk away.

How Will Custom TPE Formulations Shape the Future of Adult Products?

Your product line looks good, but let’s be honest, it looks a lot like your competitors’. In a crowded online marketplace, it is incredibly difficult to stand out. Without unique product features, you are forced to compete on price, which is a race to the bottom that erodes your margins and brand value.

Custom TPE formulations will enable brands to create truly unique sensory experiences. This goes beyond color and includes precise control over firmness (durometer), surface texture (from velvety to slick), and even thermal properties. This level of personalization allows brands to build specific niches and cater to detailed customer preferences, moving far beyond one-size-fits-all products.

Differentiation is the key to survival and growth. For years, innovation in our industry was mostly about new shapes or new motor patterns. But the material itself was often an afterthought. That’s changing fast. The next wave of successful brands will be those who master material innovation. I once worked with a client who wanted to create a "super soft" toy. Their previous supplier just gave them their standard soft TPE. We sat down and talked about the specific user experience they wanted. They didn’t just want soft; they wanted a squishy, "memory-foam" like rebound. By adjusting the TPE formulation to a specific Shore 00-20 durometer, we created a product with a unique feel that became their signature. This is the power of custom formulations.

Understanding Durometer (Firmness)

Durometer is the technical measure of a material’s hardness. For TPE, it’s typically measured on the Shore 00 or Shore A scales. Small changes in durometer can dramatically change the feel of a product. A good manufacturer won’t just offer "soft, medium, hard." They will work with you to dial in the precise durometer your product needs, allowing you to create a specific experience for your target customer.

| Shore Hardness (Example) | Common Feel | Best Suited For |

|---|---|---|

| Shore 00-30 | Extremely soft, gel-like, squishy | Products where comfort is paramount, for sensitive users, or for creating a very lifelike feel. Great for stress balls or external strokers. |

| Shore 00-50 | Soft with more resilience, a "gummy" feel | A popular choice for a wide range of toys, balancing softness with a bit of structure. A good all-purpose starting point. |

| Shore A 10-20 | Firm with noticeable flex | Ideal for internal toys like dildos or G-spot vibrators that need some rigidity for insertion but still need to be comfortable and not hard plastic. |

Advanced Texture and Haptics

Beyond firmness, the surface finish of a TPE toy is critical to the user experience. Modern formulations allow for incredible control over this. We can create a "velvety matte" finish that feels powdery and soft, a "silky smooth" finish that’s great with lubricant, or even a slightly "tacky" high-grip texture for better handling. This level of detail in haptics (the sense of touch) is a powerful way to differentiate your product. It shows a deep understanding of your customer’s desires and elevates your product from a simple object to a sophisticated experience.

The Next Frontier: Functional Formulations

We are just scratching the surface of what’s possible. The next wave of innovation will be TPE with built-in functional properties. Imagine a TPE that is thermally conductive, so it warms to body temperature almost instantly. Or a TPE that changes color with heat, providing visual feedback. We’re also developing formulations with visually stunning effects, like embedded, body-safe pearlescent pigments or glitters that are safely sealed within the material. These aren’t gimmicks; they are ways to create deeply engaging and memorable products that your customers will talk about.

How Can You Partner with a Manufacturer Who Leads in TPE Innovation?

You have amazing ideas for innovative, safe, and sustainable products that your customers will love. But finding a manufacturer who can actually execute that vision, instead of just pushing their standard, off-the-shelf options, can feel like searching for a needle in a haystack.

To find an innovative TPE manufacturer, look for one who proactively discusses material science, not just price. They should be able to explain their material sourcing, provide detailed safety certifications (REACH, RoHS), and offer a wide range of custom options like durometer and bio-based content. A true partner works with you from concept to final product, offering low MOQs to help you test new ideas.

The most important decision you will make as a brand owner is not your marketing plan or your website design—it’s who you choose to manufacture your products. A cheap supplier can cost you a fortune in the long run through delays, quality issues, or recalls. A true partner, on the other hand, becomes an extension of your team. They bring expertise to the table, help you avoid pitfalls, and are invested in your success. Shifting your mindset from finding a "supplier" to finding a "partner" is the first step toward building a resilient and innovative brand.

The ‘Partner’ vs. ‘Supplier’ Mindset

A supplier takes your order. They will produce what you ask for, often with minimal feedback. If there’s a problem with your design, you might not find out until you have 5,000 units of a flawed product on your hands. A partner collaborates. They ask questions. They’ll say, "We see you’ve requested Shore A 10 for this design, but given its thin neck, we recommend a slightly firmer TPE to prevent tearing. Can we send you a sample of both to compare?" That kind of proactive advice is priceless. It saves you time, money, and protects your brand’s reputation. A partner doesn’t just want your purchase order; they want you to succeed so you’ll place more orders in the future.

Essential Checklist for Vetting a TPE Manufacturer

How do you spot a true partner? Look for these key signals during your vetting process.

[ ]Transparency: Do they openly and quickly share their material data sheets, third-party test reports (REACH, RoHS), and quality control procedures?[ ]Expertise: Can their engineers and sales staff have an intelligent conversation about the pros and cons of different TPE formulations for your specific product idea? Or do they just talk about price?[ ]Customization Capabilities: Do they offer custom durometer, color matching, textures, and bio-based options? Crucially, what are their MOQs (Minimum Order Quantities) for these custom runs?[ ]Sustainability Roadmap: Do they have a clear plan for incorporating more sustainable materials and practices? Are they just reacting to trends, or are they actively investing in a greener future?[ ]Communication: Are they responsive, clear, and fluent in your language? Small misunderstandings due to language barriers can lead to huge production mistakes.

Why Low MOQs and Fast Sampling Are Critical for Innovation

Innovation requires experimentation, and experimentation means testing things. If a manufacturer demands a 5,000-unit MOQ for a new color or a slightly different firmness, you’ll never be able to innovate. It’s too risky. A partner who supports innovation will offer low MOQs and a fast, affordable sampling process. This allows you to test new ideas with a small batch, gather market feedback, and make adjustments before committing to a large production run. This flexibility is the lifeblood of a modern, agile brand. When a manufacturer offers this, they are showing you that they are confident in their abilities and are willing to grow with you.

Conclusion

The future of TPE in the adult products industry is incredibly exciting. The market is shifting decisively towards products that are safer, more sustainable, and highly personalized. By demanding certified materials, exploring custom formulations, and choosing a true manufacturing partner, you can build a brand that customers deeply trust and love.