Worried about inconsistent TPE quality ruining your product launch? A single bad batch can destroy customer trust and your brand’s reputation. Proper process validation documentation is your assurance, proving your manufacturer meets the highest standards for every single product they make for you.

Process validation for TPE adult products requires a comprehensive documentation package. This includes a Validation Master Plan (VMP), protocols and reports for Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). These documents prove that the manufacturing process is controlled, consistent, and capable of producing products that meet all predefined quality and safety specifications, ensuring reliability from batch to batch.

This strict documentation might seem like a lot of work, but it’s the foundation of a reliable supply chain. As a brand owner, you don’t need to be an expert in validation, but you do need to know what to ask for. Understanding these documents empowers you to choose a manufacturing partner who truly values quality. I’ve spent years refining our processes here at PrivyPlay, and I can tell you firsthand that it’s this meticulous attention to detail that separates the best from the rest. Let’s break down exactly what goes into a robust validation process.

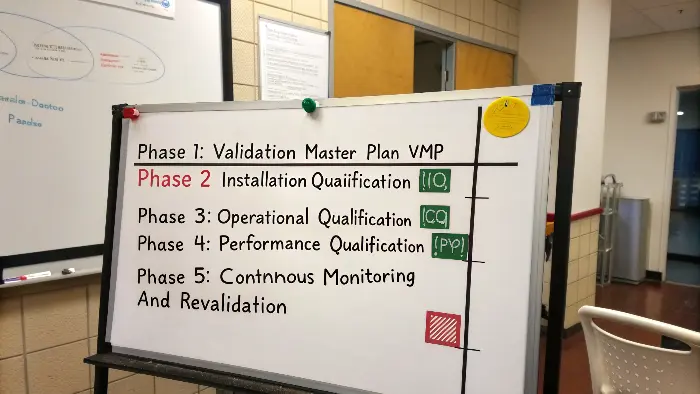

What are the 5 major phases in the validation process?

Ever feel like you’re in the dark about your manufacturer’s process? This uncertainty can be stressful, especially when your brand’s quality is on the line. Knowing the five phases of validation gives you a clear roadmap to follow, ensuring transparency and control at every step.

The five major phases of validation are: Phase 1: Validation Master Plan (VMP) creation. Phase 2: Installation Qualification (IQ) to check equipment setup. Phase 3: Operational Qualification (OQ) to test process parameters. Phase 4: Performance Qualification (PQ) to verify the process under real conditions. Phase 5: Continuous Monitoring and Revalidation to maintain the validated state over time.

Understanding these five phases moves you from being a hopeful client to an informed partner in the manufacturing process. It’s the difference between asking "Is it good?" and asking "Show me the PQ report for the last production run." When we work with a new brand owner, we walk them through this framework so they have complete confidence.

Phase 1: The Blueprint (Validation Master Plan – VMP)

Think of the VMP as the master strategy document. It outlines the company’s entire approach to validation. For you as a brand owner, seeing a well-structured VMP from a potential manufacturer is a huge green flag. It should define the validation policies, the products and processes to be validated, the required documentation, and the personnel responsible. It’s the document that proves they have a plan, rather than just reacting to problems.

Phase 2 & 3: Setting the Stage (IQ/OQ)

Installation Qualification (IQ) and Operational Qualification (OQ) are where the rubber meets the road.

- IQ confirms that the equipment, like an injection molding machine, is installed correctly and matches the required specifications. The documentation for this phase includes machine manuals, calibration certificates for sensors, and a checklist confirming everything is properly connected and identified.

- OQ tests the machine to ensure it operates correctly within predefined limits. For a TPE dildo, this means testing and documenting the acceptable ranges for barrel temperature, injection speed, and cooling time. We challenge the system at its upper and lower limits to prove we can still make a perfect product.

Phase 4 & 5: The Main Event and Beyond (PQ & Monitoring)

Performance Qualification (PQ) is the final test before full-scale production. Here, we run multiple consecutive batches under real-world conditions to prove the process is consistent and reliable. The PQ report is your ultimate proof that the manufacturer can repeatedly make your product to spec. After validation, we move into Continuous Monitoring. We keep meticulous batch records and monitor critical process parameters to ensure nothing drifts out of the validated state.

| Validation Phase | Key Question Answered | Essential Documentation |

|---|---|---|

| VMP | What is our overall strategy for validation? | Validation Master Plan Document |

| IQ | Is the equipment installed correctly? | Installation Checklists, Manuals, Calibration Records |

| OQ | Does the equipment operate within set limits? | OQ Protocol and Report, Parameter Range Studies |

| PQ | Can the process consistently produce a quality product? | PQ Protocol and Report, Data from 3+ Batches |

| Monitoring | Is the process still under control? | Batch Records, Change Control Logs, Revalidation Reports |

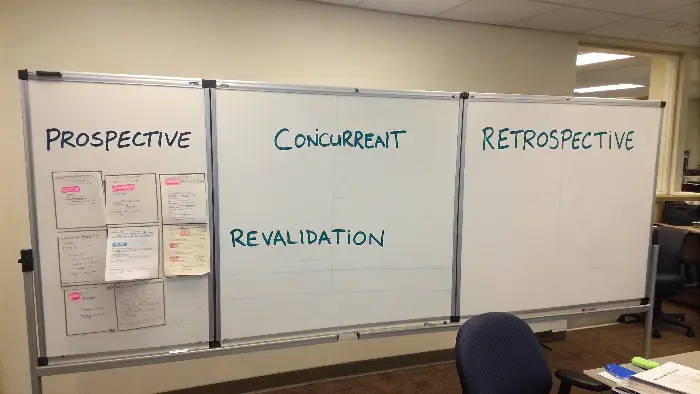

What are the 4 types of process validation?

Does a "one-size-fits-all" approach to validation make you nervous? It should. Different situations, like a new product launch versus a minor material change, require different validation strategies. Using the wrong type can lead to wasted time, money, and potential quality issues down the road.

The four types of process validation are Prospective, Concurrent, Retrospective, and Revalidation. Prospective validation is done before routine production begins for a new product. Concurrent validation occurs during routine production. Retrospective validation analyzes past data, though it’s less common now. Revalidation is performed when changes are made to the process or materials, ensuring continued compliance and quality.

Choosing the right type of validation for the right situation is critical for efficiency and quality assurance. In my experience, a mature manufacturer knows exactly which tool to use for the job. For your brand, understanding these types helps you have more meaningful conversations about your product lifecycle.

Prospective Validation: The Gold Standard

This is the most common and preferred method. It’s performed before you launch a new adult toy or introduce a new manufacturing process. When a client comes to us at PrivyPlay with a brand-new TPE vibrator design, we always perform prospective validation. We complete the full IQ, OQ, and PQ phases on a pilot batch. This comprehensive approach establishes documented evidence that the process works as intended before a single unit is shipped to a customer. It’s all about preventing problems, not just catching them. The documentation is extensive, including the full validation plan, protocols, and a final summary report that approves the process for routine manufacturing.

Concurrent Validation: For Special Cases

Concurrent validation is carried out during routine production. This might sound risky, but it’s used in specific, well-justified circumstances. For example, if a client needs a small, urgent run of a product with a minor modification, and the process is very well understood, we might use concurrent validation. It involves intensified testing of each batch as it’s produced. The documentation is just as rigorous as prospective validation, but it’s generated in real-time. It’s a pragmatic approach but requires a high degree of process understanding and control.

Revalidation: When Things Change

Manufacturing isn’t static. You might want to switch to a new, more body-safe TPE formula, or we might need to replace a critical part on an injection molding machine. Whenever a significant change occurs that could impact product quality, revalidation is necessary. This could be a full PQ or a more targeted assessment, depending on the nature of the change. The documentation for this is crucial; it includes a change control request, an impact assessment, and the revalidation report, which proves the process is still in a state of control after the change.

Retrospective Validation: A Look Back

This type is rarely used today for good reason. It involves validating a process based on historical batch data. It was once used for well-established processes that were never formally validated. However, regulators and quality-conscious brands now rightly insist on proactive validation. We never rely on this method for critical processes because it analyzes past performance without challenging the process itself.

What is the ISO standard for process validation?

How can you be sure your manufacturer’s quality claims are legitimate and not just marketing fluff? Without a recognized standard, you’re just taking their word for it. This leaves your brand vulnerable to partners who don’t follow global best practices for quality management and safety.

The key international standard is ISO 13485:2016, "Medical devices — Quality management systems." While adult products aren’t always classified as medical devices, this standard is the benchmark for quality manufacturing. Clause 7.5.6 specifically requires organizations to validate any process where the output cannot be verified by subsequent monitoring or measurement, which is critical for TPE injection molding.

When I was building PrivyPlay, I decided early on that we would operate according to the principles of ISO 13485. Why? Because as a brand owner myself, I know that peace of mind is priceless. Telling a client "we follow ISO 13485 guidelines" is my way of showing them we are serious about their brand’s safety and reputation. It provides a common language for quality that is understood and respected worldwide.

Why ISO 13485 Matters for Adult Toys

The core of ISO 13485 is risk management. For TPE adult products, this is critically important. The molding process happens inside a closed machine, and you can’t test every single finished toy for internal defects without destroying it. This is exactly the kind of process Clause 7.5.6 is talking about. By validating the process, we prove that if we control the inputs (TPE material, temperature, pressure), the output will consistently be a safe, high-quality product. Adherence to this standard demonstrates a commitment to:

- Traceability: Being able to trace a specific toy back to the exact batch of TPE and the machine it was made on.

- Risk Management: Proactively identifying and mitigating potential failures in the product or process.

- Process Control: Maintaining a documented, validated, and controlled manufacturing environment.

Key Documentation Under ISO 13485

For a sourcing manager evaluating a potential partner, asking to see their ISO 13485-aligned documentation is a powerful move. For process validation, this isn’t just one document, but a whole system. You should look for:

- A documented Procedure for Process Validation that defines how they handle it.

- Validation Protocols (IQ, OQ, PQ) that clearly state the acceptance criteria before the validation starts.

- Validation Reports that summarize the results, analyze the data, and explicitly state whether the process passed or failed.

- Records of Software Validation for any automated systems controlling the process.

- Clear documentation for Revalidation activities triggered by changes.

Seeing this level of organization tells you that the manufacturer has a robust Quality Management System (QMS) in place, which is the bedrock of consistent production.

What is the 21 CFR 211 process validation?

Are you aiming to sell in the US market, one of the most regulated in the world? Simply hoping your products meet the standards isn’t a strategy. Failing to understand the principles behind FDA regulations like 21 CFR 211 could lead to compliance issues or customs delays.

Title 21 CFR Part 211 outlines the Current Good Manufacturing Practice (CGMP) for finished pharmaceuticals in the US. While not directly for adult toys, its principles on process validation are a global best practice. It emphasizes collecting and evaluating data, from the process design stage through production, to establish scientific evidence that a process is capable of consistently delivering a quality product.

Some people ask me why we pay attention to a pharmaceutical regulation when we make adult products. The answer is simple: it’s the gold standard. I’ve seen factories that operate with no written procedures, and the result is always inconsistent quality. By adopting principles from 21 CFR 211, we build a system that our clients in the USA, Europe, and Australia can trust completely. It’s about holding ourselves to a higher standard.

Learning from the FDA’s Playbook

The FDA’s guidance on process validation is broken down into three stages, which provides a slightly different but complementary view to the IQ/OQ/PQ model:

- Stage 1: Process Design: This is the R&D phase. Here, you use laboratory and pilot-scale studies to understand the process and define the parameters. For a TPE toy, this means figuring out the perfect melting temperature and injection speed for a new material formula. All this exploratory work is documented.

- Stage 2: Process Qualification: This aligns with the IQ, OQ, and PQ phases we discussed earlier. It’s where you formally qualify the equipment and demonstrate that the process, at commercial scale, consistently produces the desired product.

- Stage 3: Continued Process Verification: This is ongoing monitoring during routine production to ensure the process remains in a state of control. It emphasizes that validation is not a one-time event.

What 21 CFR 211 Principles Mean for Your TPE Products

For a brand owner, a manufacturer who follows these principles provides tangible benefits. The documentation you can expect to see is far more robust. It means they will have:

- Written Procedures: There is a standard operating procedure (SOP) for everything, from receiving raw TPE material to the final packaging of your product.

- A Strong Quality Unit: They have a department that is independent of production, with the authority to approve or reject batches. This prevents a "fox guarding the henhouse" situation.

- Exhaustive Batch Records: Every single production run will have a detailed batch record that documents every critical step, every material lot number used, and every quality check performed.

When you ask a potential partner about their validation process, listen for these concepts. If they talk about scientific evidence, process design, and continued verification, you know you’re talking to a professional who can meet the expectations of the most demanding markets.

Conclusion

Process validation documents are not just bureaucratic paperwork. They are the tangible proof of a manufacturer’s commitment to quality, consistency, and the safety of your customers. Understanding what to ask for—from the VMP to PQ reports—is crucial for your brand’s long-term success and your own peace of mind.